- +49 (160) 95 36 60 33

- 08:00 - 17:00

- info@sapphirepetroleum.com

- Select Language

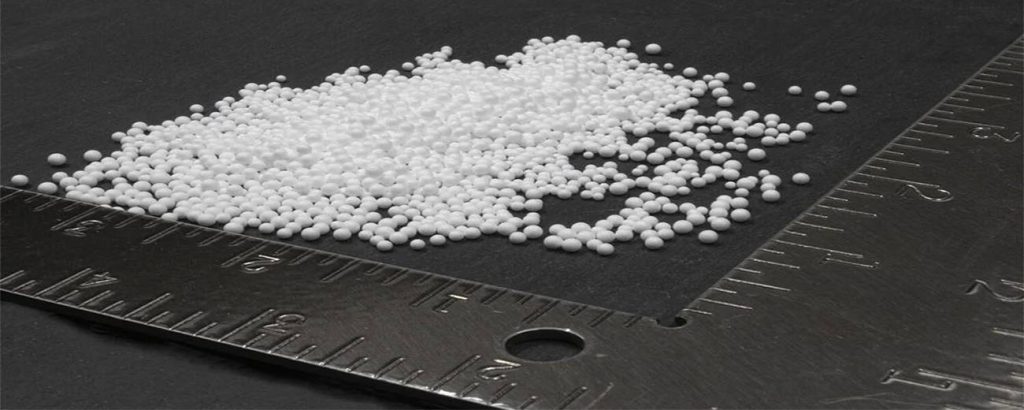

At Sapphire Petroleum Company, we are proud to offer Polystyrene (PS), one of the most widely used thermoplastics in the world. Known for its versatility, affordability, and excellent performance in a wide range of applications, Polystyrene is an essential material in industries ranging from packaging to electronics and beyond.

3. Expanded Polystyrene (EPS)

• Applications:

• Insulation materials for construction (thermal insulation).

• Packaging for fragile items (electronics, appliances).

• Disposable cups and plates.

• Features:

• Lightweight with excellent shock absorption.

• Superior thermal insulation properties.

4. Extruded Polystyrene (XPS)

• Applications:

• Construction (roof and wall insulation).

• Cold storage panels.

• Protective packaging.

• Features:

• High compressive strength.

• Moisture-resistant for long-term durability.

5. Flame Retardant Polystyrene

• Applications:

• Electrical and electronic components.

• Fire-safe building materials.

• Features:

• Flame resistance for compliance with safety standards.

6. Syndiotactic Polystyrene (SPS)

• Applications:

• Automotive components.

• High-performance electrical parts.

• Industrial applications.

• Features:

• High thermal resistance.

• Excellent chemical and mechanical properties.

1. General Purpose Polystyrene (GPPS)

• Applications:

• Food packaging containers (cups, lids).

• Clear plastic products (CD cases, display boxes).

• Stationery and household items.

• Features:

• High clarity and rigidity.

• Economical for general-purpose uses.

2. High Impact Polystyrene (HIPS)

• Applications:

• Durable packaging (yogurt containers, trays).

• Electrical components (enclosures, casings).

• Toys and decorative items.

• Features:

• Improved toughness and impact resistance.

• Easy to process for a wide range of applications.

…

Polystyrene is a synthetic thermoplastic polymer made by the polymerization of styrene monomers, which are derived from petroleum. First developed in the early 20th century, polystyrene has become one of the most widely used plastics due to its versatility, affordability, and ease of manufacturing.

Polystyrene is used in a variety of applications, including packaging materials, disposable cutlery, insulation, and consumer products. Its lightweight and insulating properties make it particularly valuable in industries like construction and food service.

Chemical Structure:

Polystyrene is composed of long chains of styrene units (C₈H₈). It can exist in two primary forms:

Key Characteristics:

Economic Impact:

Polystyrene is a cost-effective material widely used across industries, driving economic benefits in packaging, construction, and consumer goods sectors.

Industrial Applications:

Environmental Impact:

Polystyrene is non-biodegradable and contributes significantly to plastic pollution, particularly in the form of discarded packaging and foam products. Its production also involves high energy consumption.

Sustainability Efforts:

Innovations in Polystyrene:

Advancements in additives and processing technologies are improving the durability, recyclability, and environmental efficiency of polystyrene products.

Role in Emerging Applications:

Polystyrene is being adapted for innovative uses, such as in lightweight structural components, 3D printing, and renewable energy projects, including insulation for green buildings.

Polystyrene

Polystyrene (PS) is a synthetic thermoplastic polymer made through the polymerization of styrene monomers. It is valued for its versatility, transparency, and ease of processing. Key parameters in its analysis include:

– General Purpose Polystyrene (GPPS): ~1.04–1.06 g/cm³.

– Expanded Polystyrene (EPS): ~0.01–0.05 g/cm³ due to its foam structure.

Standards such as ASTM D638, ISO 527, and ISO 1622 govern its physical and chemical property testing.

Polystyrene production is concentrated in regions with significant petrochemical infrastructure. Key producers include:

Polystyrene is categorized based on its composition and application:

Polystyrene is widely used due to its cost-effectiveness and adaptability:

SAPPHIRE PETROLEUM COMPANY

© 2024 All Rights Reserved | Powered by Netologist

Reviews

There are no reviews yet.